JONA CM-IN 1250

Every customer wants to have concrete blocks of identical height with a smooth surface, therefore, the concrete blocks have to be calibrated and grinded.

Calibration and grinding machines mills out the unevenness of the concrete blocks, thus enabling the production of high-quality and precise concrete blocks.

The JONA Company produces two types of block grinding and calibration machines.

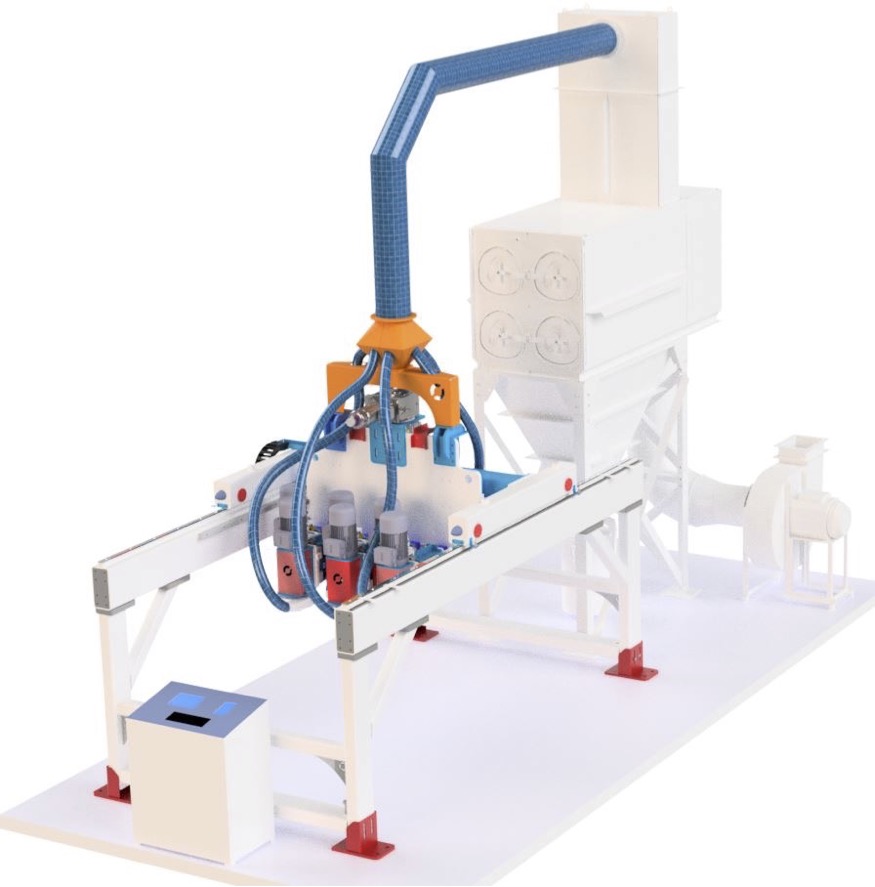

JONA CM-IN is a block calibration and grinding machine, which is integrated into the production cycle.

JONA CM-SE is free standing, thus it is independent on the production cycle.

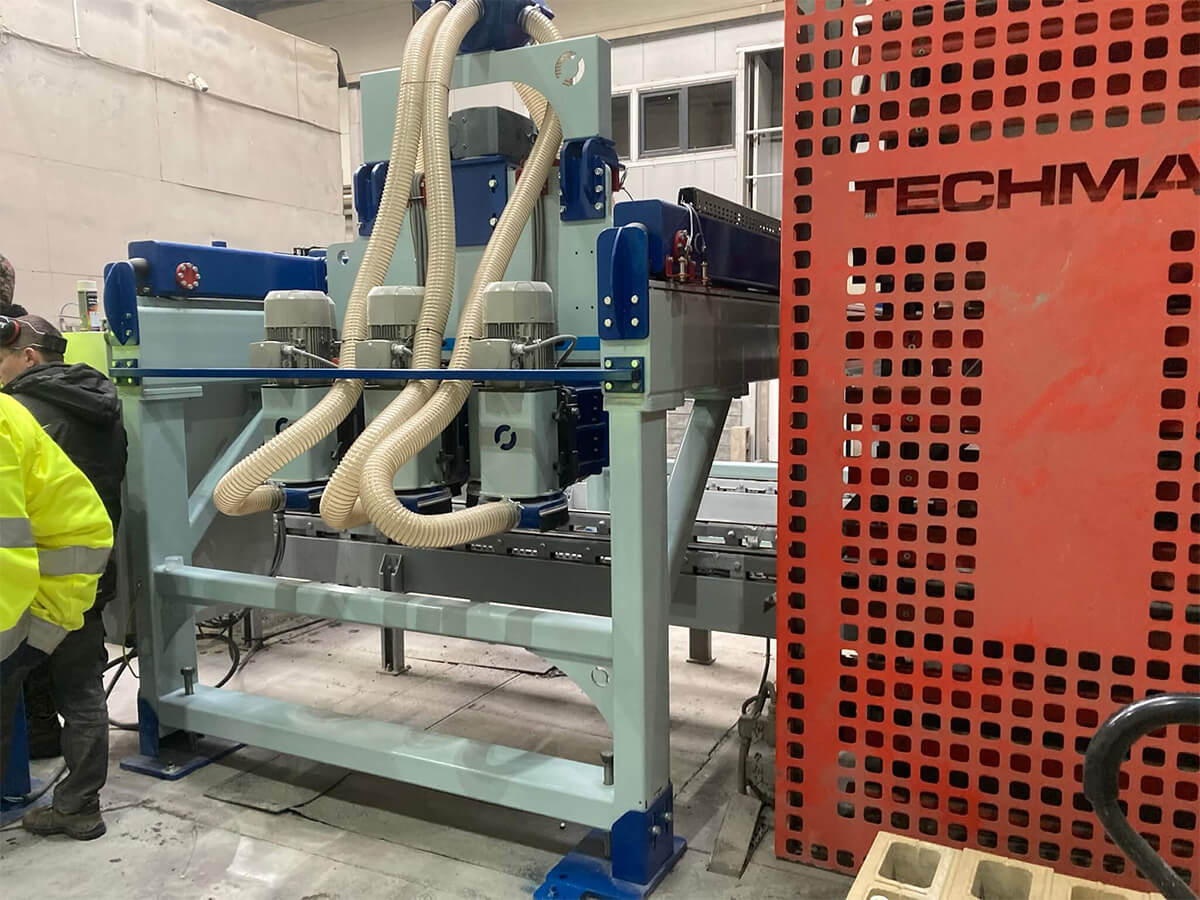

The machine is designed for the final finishing of masonry, chimney and formwork blocks. It stands out for its stability and robustness of its construction.

Advantages of the JONA CM-IN calibration and grinding machine

integration into the production process

dry grinding method

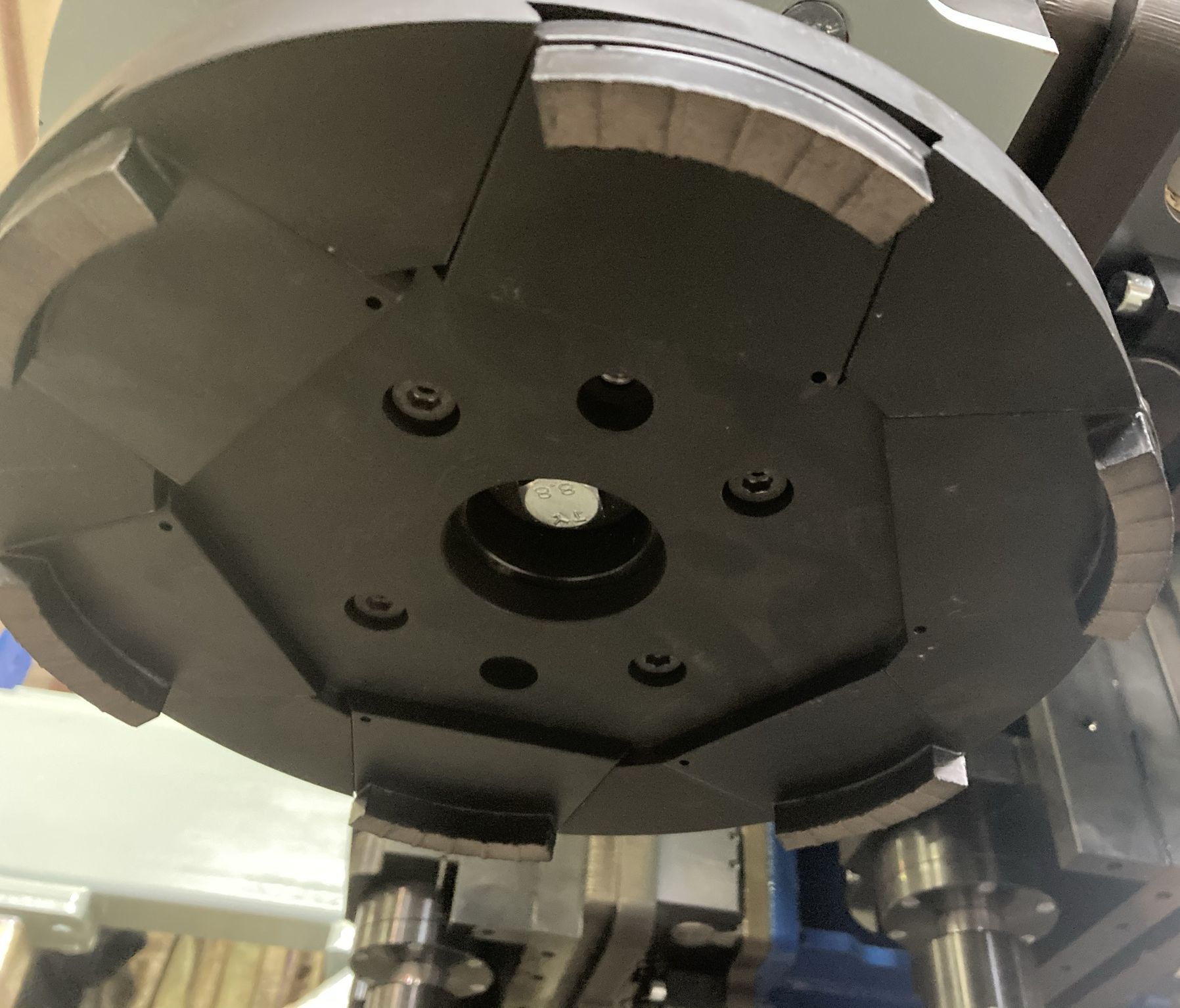

quick and simple change of the grinding segments

thanks to the dovetail guide

low energy consumption

Input: 25kW machine + 11kW suction device

The block calibration and grinding machine is equipped with high-performance milling diamonds, which are part of the universal and easily adjustable grinding wheels.

If it is nedeed to include the block calibration and grinding machine into existing production, we use 3D laser space scanning method of contactless coordinate measurements, when required. We transfer the production premises with the machinery into a 3D program, where our engineers can work on customization of the machine. This eliminates errors that might arise during measurements.

The JONA CM-IN block grinding and calibration machines, produced by our company, have proven to be exceptionally durable through daily usage in the operations of leading concrete block manufacturers.

Advantages of the JONA CM-SE calibration and grinding machine

independent on the production cycle

Free standing

low energy consumption

Input: 33kW

dry grinding method

quick and simple change of the grinding segments

The CM-SE free standing block calibration and grinding machine allows the calibration of blocks, which is independent from the production cycle and thus more flexible.

At the entrance into the machine, the blocks are placed linearly, in one line one after another. The grinding process occurs incrementally, with each block passing through a sequence of grinding wheels set at progressively lower levels. The final calibration height is determined by the last grinding wheel.

The choice between the free standing or the integrated machine depends on the specific requirements of the production, available space and technological preferences of the manufacturer.

View flyer

Gallery

Contact us

If you have any questions, do not hesitate to contact us.