Experiences

Over thirty years of designing and manufacturing moulds for concrete block making machines, we have gained extensive experience in the production of moulds for machines made by brands such as Hess, Masa, Adler, Omag, Techmatik, Columbia, Quadra, Demler, Pierre & Bertrand, Balbinot, Sigma, Zenith, and Ame.

Material

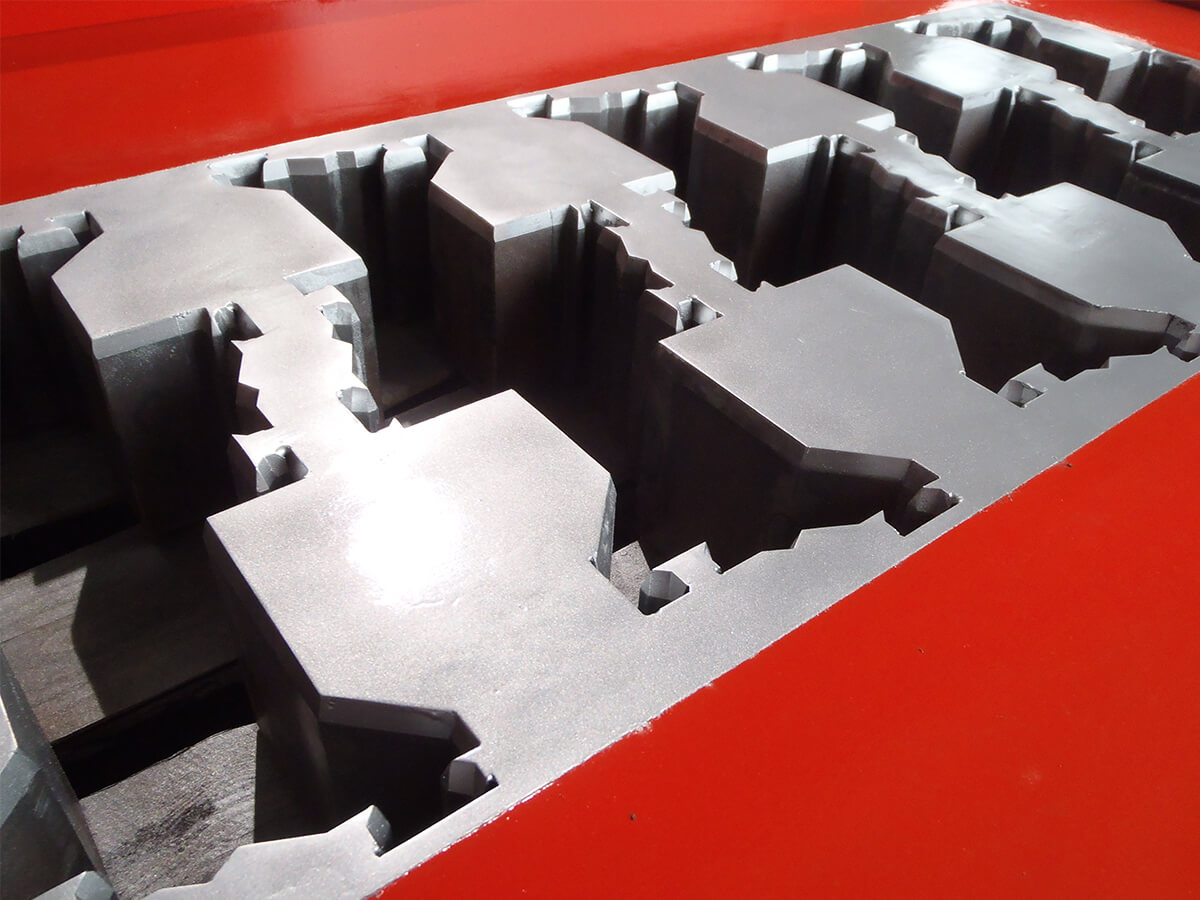

In cooperation with European experts and through testing, we have determined the materials for the production of moulds of the highest quality and longest durability. As new steel mixtures are constantly being added, we never stop in our material research. We have also increased the durability of our products through the process of heat treatment: hardening, nitriding, and cementing.

Technology

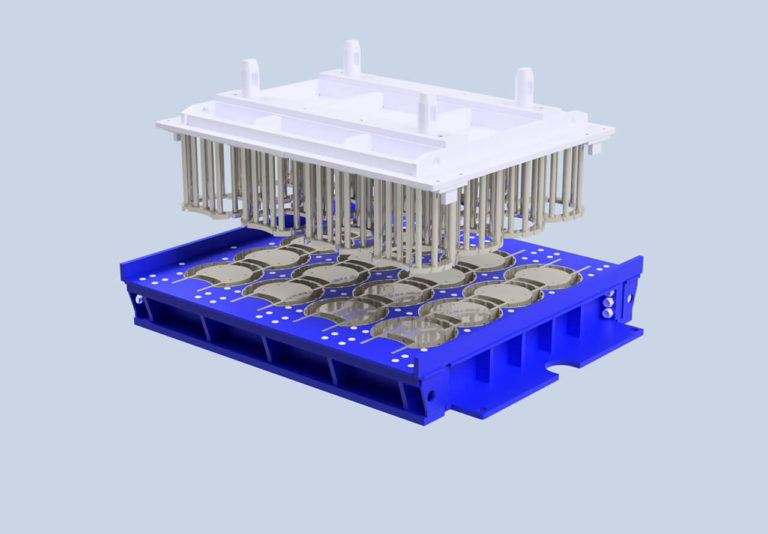

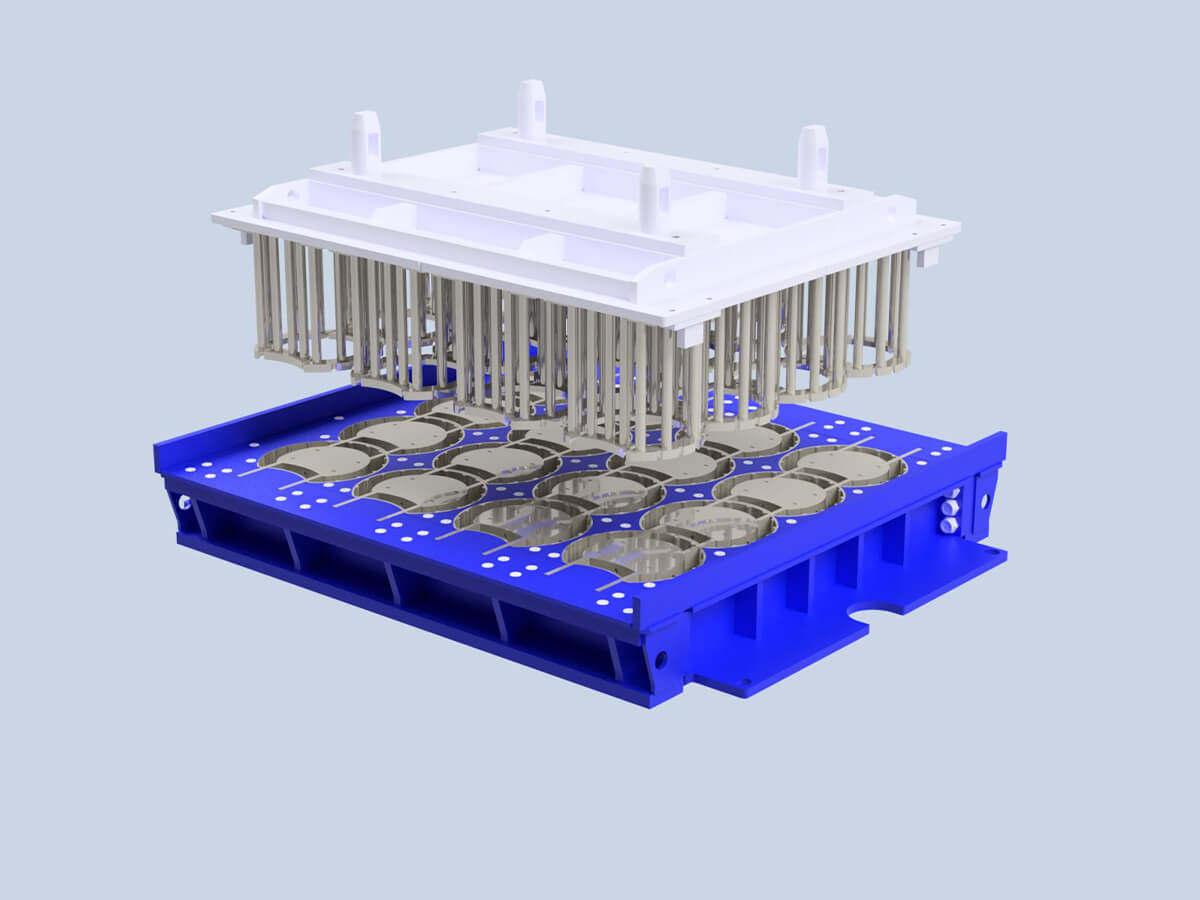

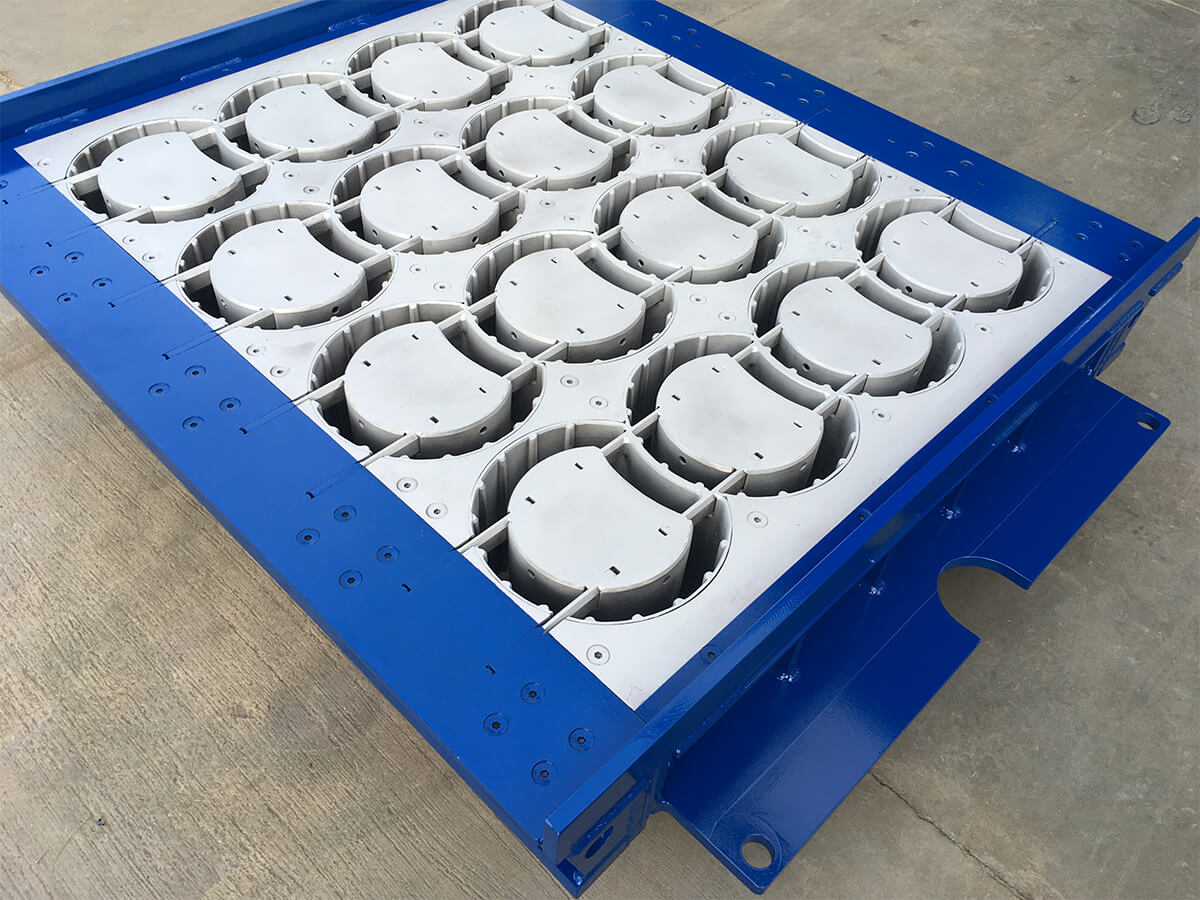

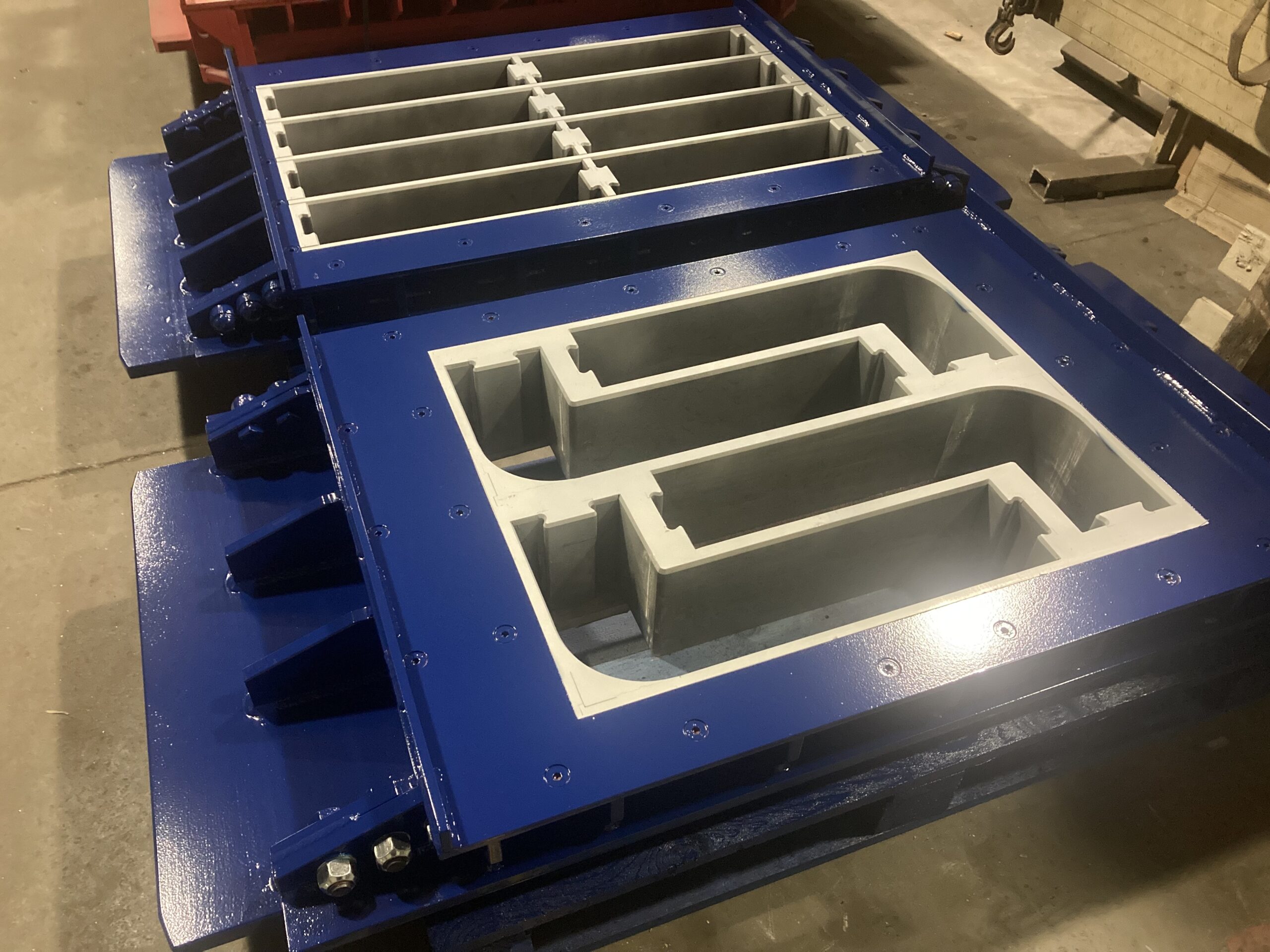

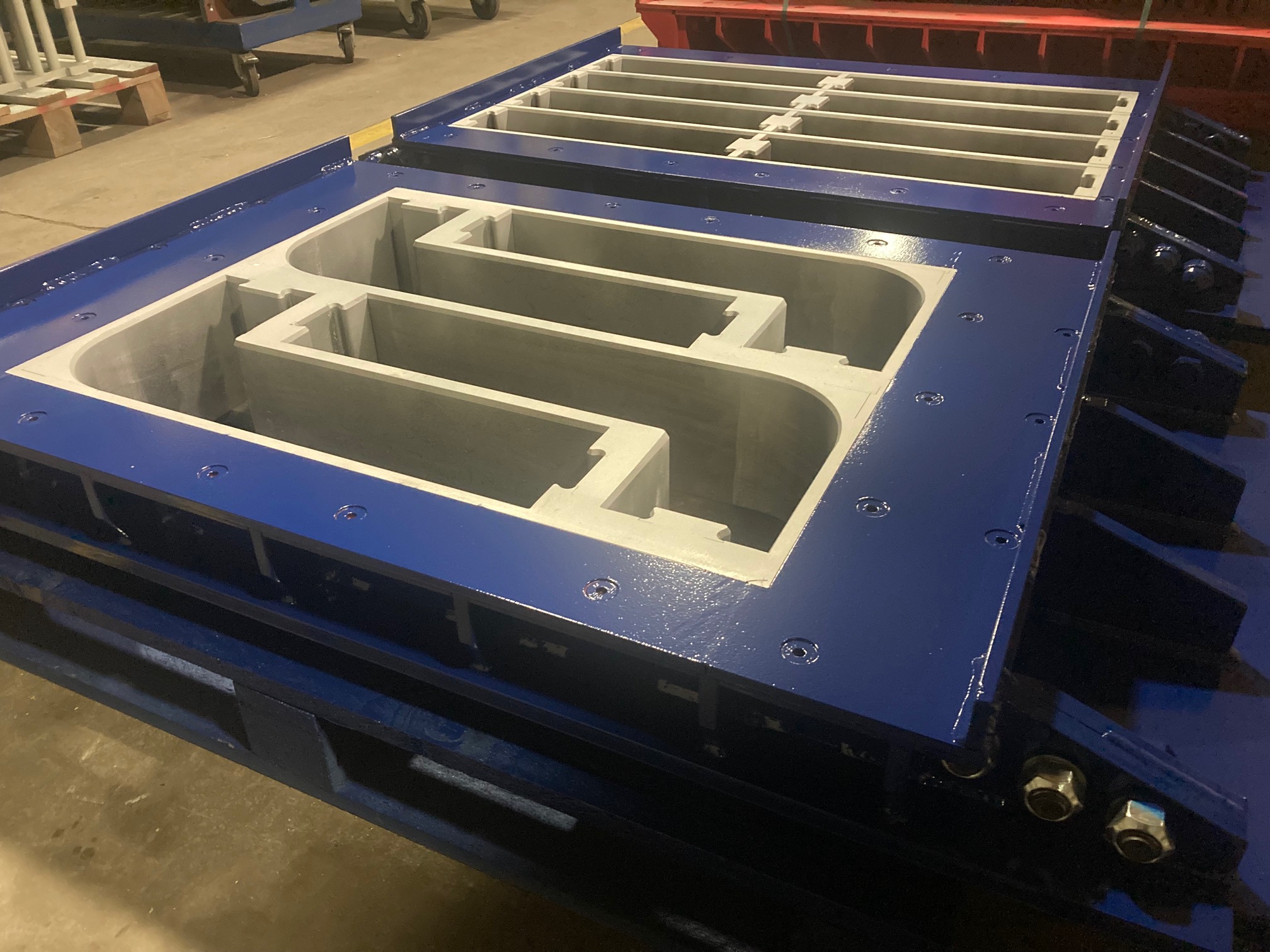

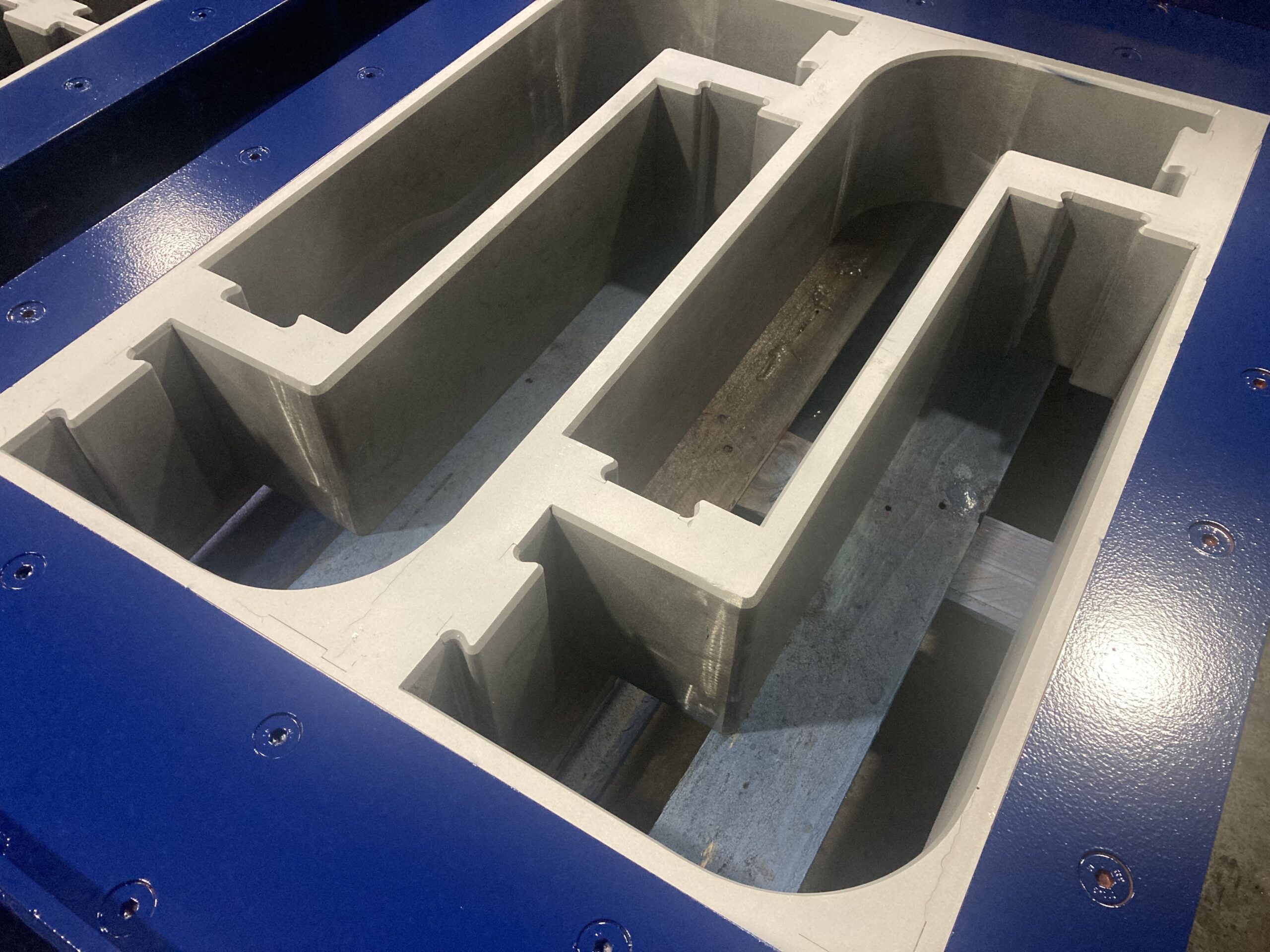

In the interest of efficient management for our customers, fifteen years ago our company developed moulds (which we still produce) for the production of prefabricated concrete blocks which are then assembled. This type of mould is designed so that its individual parts can be dismantled and are therefore easily replaceable.

Design

The current trend is for a great diversity in the product portfolio. Manufacturers of concrete elements must take this fact into account, constantly innovate their products, and keep up with development trends. The innovative approach in particular is a powerful tool for increasing competitiveness. Special moulds reflect this need by allowing the production of atypical moulds: prototypes developed, designed, and constructed to meet specific customer requirements.

We also offer other types of steel moulds to concrete blocks producers: Ceiling block moulds, Hollow block moulds, Chimneystone moulds, Curbstone moulds, Beton block moulds.

Moulds designed for the production of modular concrete blocks with a natural stone relief, suitable for building retaining walls and maintenance-free fences, are the new item in our portfolio.

We also deal in the design and production of atypical steel precast concrete moulds.

Gallery

Mould repairs and service

We carry out repair and service of moulds of all mould manufacturers.

The repairs of moulds for concrete block making machines include:

- general repairs and modernization,

- swiftmanufacture and replacement of spare parts,

- centeringof punches,

- welding of damaged mold frames.

Contact us

If you have any questions, do not hesitate to contact us.